5 Steps to Greater Maintenance Efficiency

By – Aubrey Felton – Executive Vice President – Vector Fleet Management

Do you struggle to keep your shop running efficiently and meeting production goals? Are your customers frustrated with excessive turn-around times for basic services and repairs? For most, there seems to be no clear, quick answer. VFM hopes to answer any questions in this article, “5 Steps to Greater Maintenance Efficiency.”

A physical and verbal walk-through could be the starting point.

In most under-performing shops, there are some key commonalities to be on the lookout for: (Steps Greater Maintenance Efficiency)

- A poorly designed intake process

- An un-defined repair order distribution process

- Lack of “work in process” timeline tracking & client updating of repair status

- Standard repair time guidelines in place for technicians

- Disorganized parts and supplies procurement

To find any potential problems, review the entire service delivery procedure with your clients. In this article, “5 Steps to Greater Maintenance Efficiency,” we will examine each of these areas.

Intake Process

The intake procedure starts before your customer transfers their asset to the company. It usually begins with a PM Service notification from your department. The other possibility is an on-road failure requiring a tow-in. In both scenarios, your client feels inconvenienced. They find the experience of having their automobile picked up and going through the process as exciting as seeing the dentist. An easy measure to institute is an online appointment scheduling program. There are many off-the-shelf FMIS options available that can be changed or upgraded. Allowing your clients to control their time reduces the resistance to the service process. It will provide for a more consistent bay allocation for your shop team.

When repairing a client’s car, keeping the dialogue focused on their needs is critical. What are some of the problems with your vehicle? There are certain areas of intake that you should have a questionnaire to complete. These services typically include air conditioning, brakes, and drivability. It can be frustrating when a technician gets a service order stating that the air conditioner isn’t working. Can you tell me where they think the problem is? They may spend time trying to reproduce or find the issues with the product.

As an example, here are some basic A/C questions to start with:

- Are there any dash lights on?

- Is the problem intermittent?

- Has the issue been getting worse over time?

- Does the fan work?

- Does the air blow cool/warm/hot?

- Is there anything else we should know?

This aligns with the 3 C’s every repair order should document (Concern, Cause, and Correction). The technician is responsible for accurately recording the Cause and the Correction, while your intake staff is responsible for adequately documenting the Concern.

A walk-around of the vehicle with the client is something else that is frequently done wrong. Looking for any potential signs of damage or abuse? This can help identify possible issues the client may not be aware of.

Your shop is often seen as a safe business, and clients don’t understand how long it will take to service their vehicle or equipment. Intake personnel need to be aware of how important it is to manage their time during the intake process. Based on the information found on your FMIS, a realistic schedule for maintenance/inspection may be recommended.

Repair Order Distribution

The commonly quoted statement “the right tool for the job” should be the theme for your workload distribution. Every shop has a widely varying complement of technicians. Do you apply the same thought process for all services you provide or just electrical ones? A MACS-certified technician who can connect manifold gauges to an air conditioning system is not necessarily a good choice to diagnose every A/C issue.

Having adequately trained technicians on-site helps improve service turnaround time and reduces the chances of having to do a “rework” on an issue.

Work in Process Tracking & Client Updates

Have you ever had a client call you at midday to find out the status of the vehicle they dropped off the previous morning? This may be the single greatest failure point in a shop operation. You can handle intake flawlessly, but it can be a challenge if you don’t follow up or track the repair process. It starts with defining your expectations for the technician when you want to hear back from them on the “Cause & Correction.”

In most repair cases, it is best to work with your technicians to improve service efficiency. The technician can diagnose or inspect the vehicle and pass the information back to the service writer or manager before moving on to another car. This system rewards employees for completing their work efficiently and evenly, reducing downtime in the shop.

Another process to have in place are “Quarter-Day Briefs”. This is the basic blocking and tackling mentality in our business. Shop staff must huddle to keep everyone on the same page about the expectations for the equipment being processed through the shop. This service requires all team members, including shop management, parts department staff, lead technicians, and/or shop foremen. All participants are encouraged to discuss all units that are currently being serviced and those that are still pending with their clients.

Standard Repair Times

Our industry has many resources that can help us solve this problem. We mainly focus on our fleet of cars and vans. It is more likely to occur when a technician disconnects on a day when they are being paid for their work. Most technicians doing this for a while can quote you time standards without referencing any materials. Technicians on clock time don’t work as hard as those on T&M, but in general, it never seems to take the entire 1.5 hours for repairs to be completed. How many services spend more than 4 hours in one of your bays? All employees need to know the expected repair time for any asset in the store.

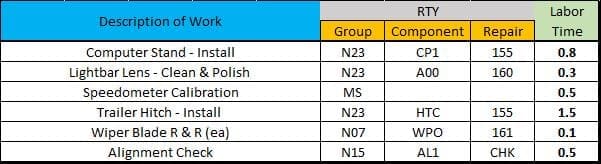

If you establish an expectation of time for an item or vehicle in your shop, your shop staff should receive flat-rate hours. When you share the work, make sure to follow the expected behavior. The person assigned to distribute repair orders is responsible for meeting the time standards and communicating with the techs in writing. One approach is to develop a document that outlines the time it takes for standard fleet services. Below is an example of a fleet-specific SRT Program:

Parts Procurement

The most challenging element of running your fleet may be acquiring components and supplies. This is not always the case. An improper part order is invariably the result of a communication failure. Technicians and parts workers commonly assume that the asset and the request are known to the other party. New data in FMIS should be kept up to date, such as an updated VIN, engine size, fluid capacity, tire size, aftermarket equipment, etc. It’s challenging to determine what the store requires since it’s still figuring out what it needs.

A straightforward example is a technician requesting an alternator. The VIN alone may not always be sufficient for the parts team to determine the required amperage alternator. The procedure belongs to both parties, thus no member of the parts staff should order an alternator without requesting the amperage. Tires are another basic illustration. To obtain the appropriate 235/55/20 tire, a technician must identify the tire’s brand, model, and performance level. Fleet maintenance is done daily at several locations around the US.

Cause for Concern

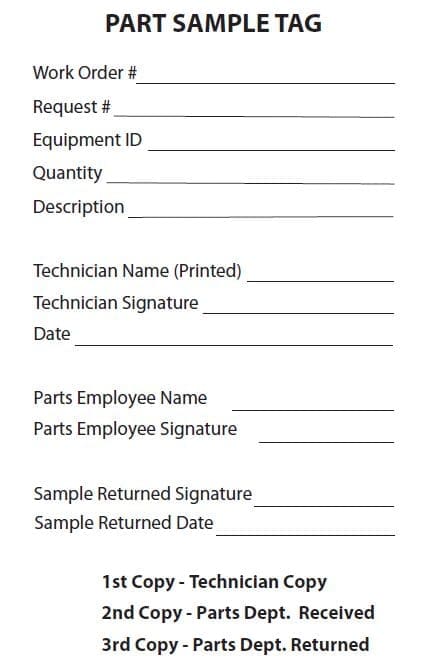

Unknown components are another cause for concern. We see this as fleet managers with obsolete or custom-built assets. A “Sample Part” procedure should be explicitly established in your organization. To assist technicians in identifying replacement components, provide a Parts Sample Tag (we advise making a carbon copy). The parts department can accept the component, search for a replacement, and hold the substitute until the replacement arrives. The technician can compare the old and new parts to guarantee compatibility.

Example of Part Sample Tag:

Hopefully, your fleet operation will have an opportunity to review these areas. Some managers have seen them take the “Undercover Boss” approach to solving these issues by working in each department of the shop. The fleet should be able to operate at a high level of efficiency to maintain its effectiveness. (Steps Greater Maintenance Efficiency)

If you want to implement changes in your shop and would like assistance and support, contact Vector Fleet Management for a free consultation.

This white paper appears on the links below:

WorkTruck

GovernmentFleet