“Kick the can down the road, until you have to deal with it” might have been good business advice when news, goods, and services were only as fast as a pony could gallop. Today, however, you simply can’t afford such antiquated business mentalities against an environment where consumer demand is immediate. Competitors are ready to take your place when you break, with unlimited options at a touch of a device.

Don’t Make The Mistake Of Ignoring Preventative Fleet Maintenance Essentials

Don’t Make The Mistake Of Ignoring Preventative Fleet Maintenance Essentials

If you don‘t prevent essentials, you may close your business temporarily or permanently.

It’s easy to fall into bad practices for quick money. The long-term financial and branding implications are often left out of sight, out of mind.

Companies reliant on 24/7 trucks are often tempted to run them until broken, making money now. It cranks and the tires turn… so why pull something not broken from the road where it can’t make money, right?

Neglecting routine tractor trailer fleet maintenance ends up costing far more in the long run, and it can leave you unable to service your customer reliably or facing major repair and replacement expenses. In addition, the damage done to your company’s reputation and brand is real and often immeasurable. Routine PM on fleet yields rewarding ROI.

Invest In A Tractor-Trailer Fleet Maintenance Program

Tractor-Trailer Fleet Maintenance Program essential for long-term financial/branding security. Why?

1. Legalities

Negligence is something you never want to hear associated with your business. DOT inspections are part of biz; let’s ensure only safe trucks/trailers on highways. Operating a truck that’s not in good condition is a legal risk you shouldn’t be willing to take. If it’s involved in an accident, you can be held liable for not keeping the truck in good working order. Fail a DOT inspection, lose time/shipment; brand name takes a hit, trust/respect lost.

2. Safety

Furthermore, in order to ensure the utmost safety, it is essential to have your trucks routinely inspected. Additionally, such efforts dedicated to safety are not only appreciated by consumers and employees, but they also help ensure your business runs smoothly on a daily basis. With the well documented shortage of CDL drivers, make your business “the safe place to work” and you attract the right drivers, as well as greatly reducing driver turnover.

3. Lower Unscheduled Maintenance

It’s less expensive, faster, and safer to stop your tractor-trailers for the short time it takes to perform regular fleet maintenance than it ever will be to send out remote technicians or tow your trucks because of emergency repairs, breakdowns, and accidents while they’re out on the road.

4. Lower Replacement Costs

Preventative maintenance can extend the life of a tractor-trailer by years, leading to predictive repairs which will further minimize downtime. The longer it lives, the less cost you have when it’s time to replace it. Plus, you get a boost in resale value.

5. Maximize Fleet Productivity

A tractor–trailer fleet maintenance program is the best way to keep trucks at peak performance without sacrificing productivity. Preventative maintenance is scheduled to minimize downtime.

What Should Be On A Preventative Maintenance Checklist?

Ensure that the following services are included in your fleet preventative maintenance plan:

- Multi-point vehicle inspection

- Adjustment

- Lubrication

- Worn part replacement

- Testing, cleaning, and repair

The schedule itself should center around engine hours, fuel usage, mileage, or a specified timeframe between services.

Your Drivers Should Assist In Fleet Maintenance

Your operators are the eyes and ears of a Tractor-Trailer Fleet Maintenance Program. They’re your first line of defense between service.

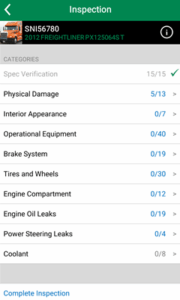

Every driver should be performing routine inspections on their truck so that unexpected problems can be immediately reported to and addressed by a certified technician. These driver-check inspections should include:

- Safety checks of brakes, lights, wipers, horn, steering, and tires.

- Drivability checks for idle issues and misfires.

- Body and glass condition checks.

- Cleanliness checks.

- Comfort and communication checks of radio and AC/heat.

- Engine and fuel efficiency checks by inspecting for coolant leaks daily, observing for warning light indicators daily, checking oil daily, noting rate of DEF consumption and checking diesel exhaust fluids, observing tailpipe for smoke, checking air filter monthly, and observing for fuel contamination when refueling.

We suggest a routine audit of driver inspections. You can perform monthly or quarterly, but the process will serve many purposes. First, it show your employees you are serious about maintenance and safety, further establishing it as a culture. Secondly, this is how you train your drivers. Just handing them an inspection form, assuming they were properly taught at their previous employer, does not drive uniformity in process. Lastly, you have the opportunity to find and address any potential issues before they arise on the route. You may just you saved yourself a big headache for the day.

Vehicle Maintenance Records

Detailed vehicle maintenance records are a crucial part of your fleet maintenance program. This history will enable you to track the timing and efficiency of repairs, manage your repair costs, chart the best maintenance practices for your specific fleet, and even help you gain vehicle value when you sell.

Detailed vehicle maintenance records are a crucial part of your fleet maintenance program. This history will enable you to track the timing and efficiency of repairs, manage your repair costs, chart the best maintenance practices for your specific fleet, and even help you gain vehicle value when you sell.

Learn more about our Fleet Maintenance Information System and onsite dedicated fleet maintenance solutions.

Consequently, the name of the game is to get the most out of every truck in your fleet, and, thus, you can’t do that by simply running through today’s problems. Eventually, you’ll be on the sidelines watching as others take over your game if you don’t have a solid prevention strategy for the essential components of your business, such as your truck fleet.

To learn more about the features and benefits of a comprehensive fleet maintenance program,

contact us today to discuss your specific needs and to get a free cost analysis.

Contact us today for a free cost analysis!