When it comes to keeping the vehicles in your fleet well maintained, three types of vehicle maintenance. “Preventive Maintenance” vehicles before problems require repair. “Demand Maintenance” provides necessary service and repairs when a particular problem develops. “Crisis Maintenance” is the most costly, providing fast action when an in-service vehicle breaks down due to a problem.

Regular maintenance of your fleet ensures safe, efficient operation of the equipment. A smart fleet owner does daily vehicle inspections, as well as inspections based on time or mileage.

Preventive Maintenance Benefits

Regular vehicle maintenance offers maximum benefits. These include:

- Fewer Accidents

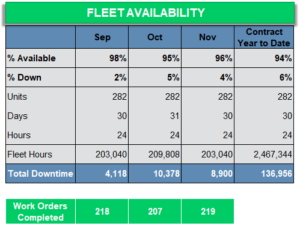

Reduction in vehicle accidents caused by tire, steering, brake and failure of other mechanical parts. - Reduced Downtime

Vehicles maximize their time on the road instead of spending time in the shop getting repaired. - Less Maintenance Costs

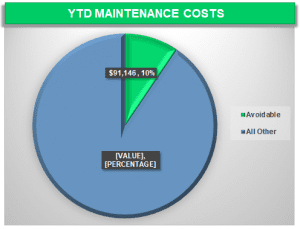

Regular inspections catch problems while they are still minor, preventing the need for most expensive repairs. - Improved Employee Morale

To ensure peak performance, commercial vehicle drivers care for their vehicles and drive carefully. - Better Public Relations

Clean and well-maintained equipment translates to improved sales and positive public perception. Your vehicles show the public that your company is safety–minded and represents your business.

Organizing Your Fleet Maintenance Program

Your first option is to perform maintenance in-house. This means investing in tools, equipment, parts, inventory, shop space and hiring qualified personnel and associated benefits costs.

In–house staff can handle preventive maintenance and minor repairs, and major repairs should be outsourced. Using less sophisticated repair equipment reduces capital expenditures, but requires a repair shop to fix your equipment quickly. A situation in which you lose control of prioritizing repairs and associated downtime.

The third and best option is to outsource your fleet maintenance to an experienced fleet maintenance company like Vector Fleet. Providing the equipment necessary for preventative maintenance, major repairs, statutory compliance, and handling all staffing requirements are all aspects of this program.

The third and best option is to outsource your fleet maintenance to an experienced fleet maintenance company like Vector Fleet. Providing the equipment necessary for preventative maintenance, major repairs, statutory compliance, and handling all staffing requirements are all aspects of this program.

A well-run fleet maintenance program keeps all vehicles in the fleet operating at top performance levels. In addition to regular inspections, the selected program should keep vehicles on the road and out of repair shops. Always observe vehicle manufacturers’ recommended specifications and regulations for optimal results.

Record Keeping Should Be Top of Mind

By keeping an accurate record of maintenance activities performed and scheduled, there is effective control and proper analysis exercised over the entire fleet. If the records kept are accurate, and current, and adequately describe specific problems and exact costs applied to each vehicle, this can be achieved. Accurate record keeping is important, whether you control a fleet of cars or heavy trucks.

Record four key areas of information in maintenance records. Specify what work was done, the date it was done, who did the work, and the costs involved. Beyond that, documenting the Concern, Cause, and Correction in the repair order detail will help to identify patterns of failure and work to improve Predictive maintenance throughout the fleet.

Management knows when to schedule maintenance services and how to judge the effectiveness of the maintenance program currently in place by referring to the recorded information. Never slash operating costs by sacrificing proper vehicle maintenance programs. Any short-term financial gains from cutting vehicle maintenance will be more than exceeded in future repair costs driven by the neglect. The best approach is more often than not preventive maintenance to save time and money when it comes to necessary repairs.

Vector Fleet offers a comprehensive fleet management information system that can provide management with a variety of cost-saving operational tools, reports and analysis. The system includes real-time access though an internet portal so end users can stay abreast of the up to the day historical cost of maintenance.

Vector Fleet custom designs all our customer maintenance programs.

We can develop a cost-saving and process-improving solution for your fleet.

Contact us today for a free cost analysis!